Built to Deliver Engineered

for Precision

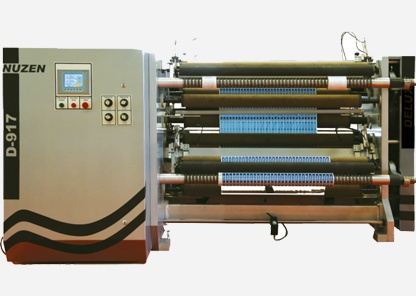

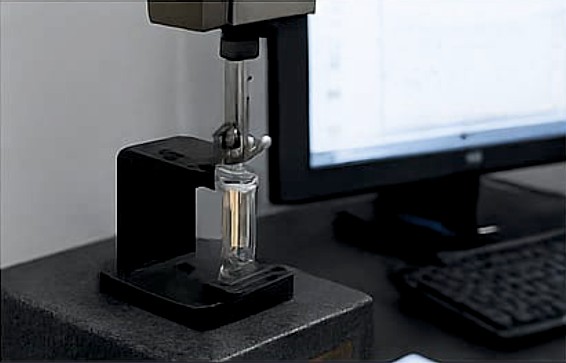

Our manufacturing facility in Faridabad, NCR is equipped to meet the evolving needs of modern brands

from short-run customization to high-volume rollstock production

We’ve invested in high-efficiency machines, streamlined workflows, and strict quality protocols to ensure every order is delivered on time, on spec, and on budget.